From idea to finished solution

Poppe works with all of the established manufacturing techniques in the rubber industry, thereby enjoying optimal technical foundations. In addition, the know-how of experienced employees and the expertise of young engineers make for an efficient combination of the proven and the innovative that allows us to find the best solution for every task.

Made by Poppe

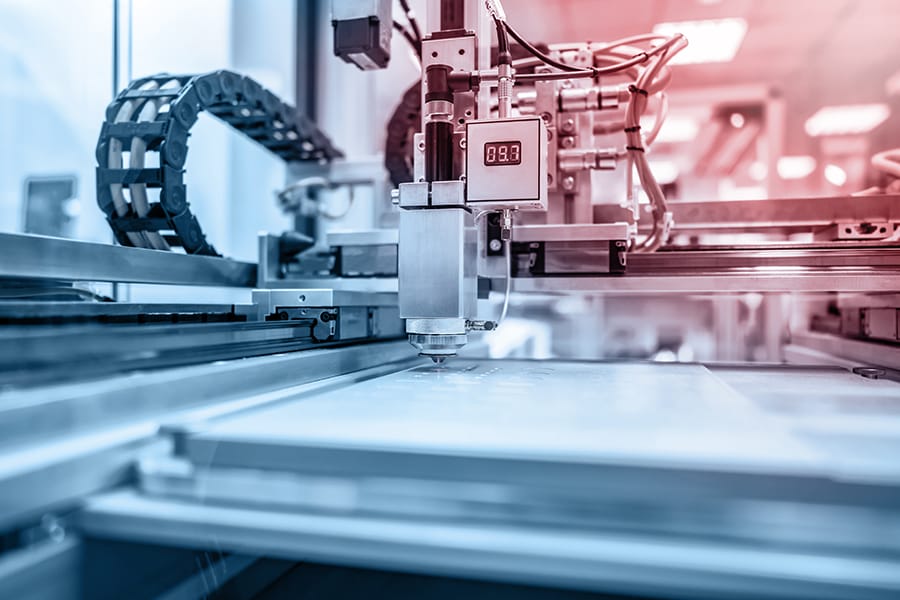

As a modern rubber processor, we constantly develop individual solutions for a wide range of applications and realize them for our customers at our sites in Gießen and Gelnhausen using extrusion or injection moulding as well as LSR (Liquid Silicon Rubber). We meet the requirements made of us with innovative products and a clever combination of different materials. With a tradition dating back more than a hundred years, today we stand for constant growth and outstanding solutions for our customers.

Knowledge and development

With the experience of more than a century in the industry and a keen eye on the challenges and possibilities of both the present and the future, we are ideally equipped to meet the demands of ever-changing tasks.

From the idea to the product

Our products and services satisfy the highest requirements in terms of quality. Our manufacturing techniques set standards. From the design phase and the development of the right material through to the finished product, we accompany you with personal consultation and expert advice throughout. The benefit for you: The optimum solution for your specific requirements from a single source

Not what you're looking for?

If you have any questions, our support representatives will be happy to help you. We are looking forward to your message.

Get in touchFrequently asked questions

Customer requirements can be taken into account individually via our in-house material development department. Furthermore, various test facilities are available, which allow all common material tests. Please contact us for a consultation.

We offer our basic ClipFix® and ClassicFix® spacers in various sizes. Existing sizes can be found in our catalog. We will be happy to implement further sizes for you.

Up to three different elastomers in one profile plus further components such as wire reinforcement, stretch protection, coatings or laminates.

Poppe products are manufactured using the extrusion process with up to three different elastomers plus wire reinforcement, stretch protection, coatings or laminates. Furthermore, we offer tool-bound products using the injection molding process for elastomers and liquid silicones (LSR).

The production takes place within the tolerances according to DIN ISO 3302-E1 and DIN ISO 3302-E